GreaseMax Auto Lubricators

A fully automatic, robust and reliable lubricant dispenser suitable for a wide variety of applications.

- Overview

- Technical

- Downloads

GreaseMax® CONTINUOUS AUTOMATIC LUBRICATORS

GreaseMax units will ensure an adequate supply of any number of points requiring regular lubrication over a given period of time, doing away with the need for time consuming checks and re-lubrication visits.

- Provides continuous lubrication at a constant rate for a set period

- Works without maintenance or adjustment

- Has no electric or mechanical parts and is reliable

- Can be quickly replaced at the end of it's operating period

- Can be used on moving and vibrating applications, even underwater

- Rate of discharge unaffected by bearing or seal condition

- 1, 3, 6 and 12 month operating periods

- A wide range of lubricant fills available

Advantages

- Simple installation and activation

- Better mechanical reliability

- Less down time

- Proven in-service performance

- Safety certificated by the TUV (Germany)

- Economical unit cost compared to other brands

- Experienced product support

- Wide range of lubricants available

- Clean and environmentally friendly

Typical applications

- Food and beverage industry

- Water and sewage plants

- Lifts and elevators

- Mining and quarrying machinery

- Process engineering

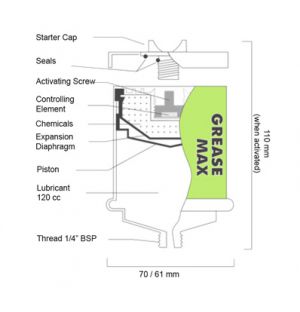

GREASE MAX® is a chemically operated automatic lubricator.

It is designed to be screwed into the bearing grease nipple seating, or onto an extension line, and to feed lubricant at a constant rate for a set period of time. There are 4 operating periods: 1, 3, 6 and 12 months. After the service time has elapsed, the unit is replaced with a new unit. Because it is self regulating it should be used in conjunction with the plant maintenance scheduling. Therefore changeovers of the GREASE MAX® can be planned and carried out at set periods.

GREASE MAX® operation is simple and trouble free. Quite frequently its capabilities are not at first appreciated because of it's simplicity. GREASE MAX® can be used anywhere; on most applications, both large and small, even underwater. Importantly, GREASE MAX® has no electrical or mechanical components and has only one moving part, which is the piston. For this reason GREASE MAX® is extremely reliable.

Discharge time and replacement of GREASE MAX®

Once the quantity of lubricant needed per lubrication point and the average temperature are known, the correct GREASE MAX® unit can be selected from the table below.

| Type 01 White 1 mth | Type 03 Blue 3 mth | Type 06 Red 6 mth | Type 12 Grey 12 mth | |||||

|---|---|---|---|---|---|---|---|---|

| Average environmental temp. | Life in months | Grease supply / day grams | Life in months | Grease supply / day grams | Life in months | Grease supply / day grams | Life in months | Grease supply / day grams |

| 65° C | 0,15 | 24,0 | 0,5 | 0,8 | 1 | 3,6 | 2 | 1,8 |

| 55° C | 0,3 | 12,0 | 1 | 3,6 | 2 | 1,8 | 4 | 0,9 |

| 45° C | 0,5 | 7,3 | 1,5 | 2,3 | 3 | 1,2 | 6 | 0,6 |

| 35° C | 0,7 | 5,2 | 2,5 | 1,5 | 4,5 | 0,8 | 9 | 0,4 |

| 25° C | 1 | 3,6 | 3 | 1,2 | 6,0 | 0,6 | 12 | 0,3 |

| 15° C | 1,5 | 2,3 | 4,5 | 0,8 | 9,0 | 0,4 | 18 | 0,2 |

| 5° C | 2 | 1,8 | 6 | 0,6 | 14 | 0,26 | 28 | 0,13 |

| -5° C | 4 | 0,9 | 12 | 0,3 | 24 | 0,15 | 48 | 0,08 |

| -15° C | 6 | 0,6 | 18 | 0,2 | 36 | 0,1 | ||

| -25° C | 9 | 0,4 | 27 | 0,13 |

Note: The average environmental temperature is the average temperature that occurs over the whole life of the unit.

Temperature variations above or below 25°C over a short period of time will have little or no affect on the overall life of GREASE MAX®. For example, periods of exceptionally hot or cold days.

The following shaft size can be taken as a guide

| Shaft Size | GREASE MAX® type |

|---|---|

| 100 mm - 160 mm | 1 mth |

| 60 mm - 100 mm | 3 mth |

| 30 mm - 60 mm | 6 mth |

| up to 30 mm | 12 mth |

Additionally, the following „rule of thumb“ may prove helpful

In terms of strokes per day from a small hand grease gun, output approx. 0.6cc per stroke, the GREASE MAX® discharge is roughly equivalent to:

| GREASE MAX® type | Strokes per day |

|---|---|

| 1 mth | 4 - 6 |

| 3 mth | 2 - 3 |

| 6 mth | 1 |

| 12 mth | 0.5 |

Accessories

A full range of adapters and fittings is available from stock. An illustrated accessory list is available from the downloads sections

| Adapter BSP .” f / M 6 x 1 m | AF060100 |

| Adapter BSP .” f / M 8 x 1 m | AF080100 |

| Adapter BSP .” f / M 8 x 1,25 m | AF080125 |

| Adapter BSP .” f / M 10 x 1 m | AF100100 |

| Adapter BSP .” f / M 10 x 1,5 m | AF100150 |

| Adapter BSP .” f / M 12 x 1,5 m | AF120150 |

| Adapter BSP .” f / M 12 x 1,75 m | AF120175 |

| Adapter BSP .” f / M 14 x 2 m | AF140200 |

| Adapter BSP .” f / M 16 x 1,5 m | AF160150 |

| Adapter BSP .” f / BSP 1/8“ m | AF000108 |

| Adapter BSP .” f / BSP .“ m | AF000104 |

| Adapter BSP .” f / BSP 3/8“ m | AF000308 |

| Adapter BSP .” f / BSP .“ m | AF000102 |

| Hexagon Nipple BSP .” m, m | AX000104 |

| Sleeve BSP .“ f, f | AM104000 |

| T - Adapter for two Lubricators BSP .” f, f, m | AT000104 |

| Non – Return Valve for Oil Units BSP .“ f, m | AR000104 |

| Oil Brush 5 x 3 cm, BSP .“ f | AP020045 |

| Angle 45° BSP .“ f, m | AW450104 |

| Angle 90° BSP .“ f, m | AW900104 |

| Clamp for GREASE MAX® | AH000500 |

| Clamp for Non - Return Valve | AH000501 |

| Tube Nylon 6/8 mm X 1 meter | ASS00100 |

| Tube Connection Lubricator 6/8 mm / BSP .“ f | ASI00104 |

| Tube Connection Greasing Point 6/8 mm / BSP .“ m | ASA00104 |

| Tube Connection Greasing Point 6/8 mm / BSP 1/8“ m | ASA00108 |

| Extension Metal BSP .“ f, m / 30 mm | AM104030 |

| Extension Metal BSP .“ f, m / 80 mm | AM104080 |

| Extension Metal BSP .“ f, m / 120 mm | AM104120 |

Lubricants

GreaseMax units are available with the following grease fills:-

F001 General purpose EP grease

Universal lubrication of plain, ball and roller bearings for plant, equipment and vehicles. Contains highly effective EP additives and has good adhesion and corrosion protection. Optimum lubrication performance even under extreme conditions. Operating temperature range -30°C to 120°C. Equivalent to SKF LGEP2 and LGMT2.

F002 High temperature grease

From -30°C to 150°C / 170°C short term. Special grease for a wide temperature range. Suitable for highly loaded plain and rolling bearings, joints, hinges and guides. Long-term properties, water and steam resistant, resistant to aqueous acids and alkalis. Equivalent to SKF LGHP2, LGWA2 & LGWM1.

F003 Multi purpose grease for plain bearings + MoS2

Normal to heavily loaded plain and roller bearings even in dusty and moist conditions. Emergency lubrication properties with solid lubricant MoS2.

F004 CV joint/ high temperature Grease + MoS2:

Highly loaded plain and roller bearings, wide temperature application range, long-term and emergency lubrication features, resistant to aggressive media.

F006 open gear grease

For the lubrication of gears and linear guides. Good pumpability. Suitable for extension lines for hard to reach lubrication points.

F100 Food Grade Grease NSF-H1

Synthetic high performance grease for the food, pharmaceutical and stock feed industries. Universally applicable, high power reserves at -40°C to + 180°C. Equivalent to SKF LGFP2.

F176 Extreme temperature grease

A Perfluropolyether grease for plain and rolling bearings in extreme temperature applications such as tunnel ovens, furnaces and boilers, conveyor ovens etc. Equivalent to LGET2.

F177 Ultra heavy duty grease

A lithium soap grease for the lubrication of very heavily loaded plain and roller bearings. Equivalent to SKF LGEV2.

F219 High load, high temperature grease

A calcium sulfonate lithium complex grease with superb water resistance suitable for the lubrication of a wide range of rolling bearings in wet, hot applications.Equivalent to SKF LGHB2.

F239 Specifically for QCB Slew drives

An anti-wear grease which combines the features of a synthetic base fluid with an organo-clay (non soap) thickener compatible with the factory specified grease used in QCB Slew drives

For assistance in the selection of lubricant talk to our Technical team

Downloads included data on GreaseMax installation and operation, accessories and the grease range available

(PDF) 526.44 KB

(PDF) 1,147.63 KB

(PDF) 1,070.16 KB

(PDF) 1,071.20 KB

(PDF) 1,071.36 KB

(PDF) 1,143.47 KB

(PDF) 1,227.63 KB

(PDF) 1,118.58 KB

(PDF) 1,116.40 KB

(PDF) 1,082.39 KB

(PDF) 1,038.57 KB