SSUCF Series

Solid base 4 bolt square flange units available with SCO (open) or SCC (closed end) caps

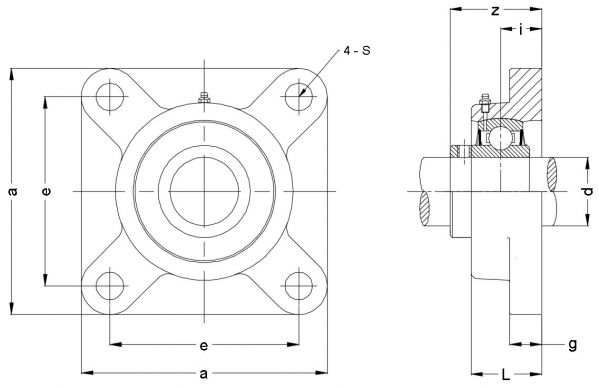

- Dimensions

- Technical

- Downloads

| QCB ref | Dimensions | Bolt size | |||||||||||

| a | e | g | L | i | z | s | |||||||

| mm | inch | mm | mm | mm | mm | mm | mm | mm | kg | ||||

| SSUCF 201 SB | 12 | 1/2 | 86 | 64 | 12 | 25.5 | 15 | 33.3 | 12 | M10 | 0.58 | ||

| SSUCF 202 SB | 15 | 5/8 | |||||||||||

| SSUCF 203 SB | 17 | 11/16 | |||||||||||

| SSUCF 204 SB | 20 | 3/4 | |||||||||||

| SSUCF 205 SB | 25 | 7/8 | 15/16 | 1 | 95 | 70 | 14 | 27 | 16 | 35.8 | 12 | M10 | 0.83 |

| SSUCF 206 SB | 30 | 1.3/16 | 1.1/4 | 108 | 83 | 14 | 31 | 18 | 40.2 | 12 | M10 | 1.1 | |

| SSUCF 207 SB | 35 | 1.1/4 | 1.3/8 | 1.7/16 | 116 | 92 | 15.5 | 34 | 19 | 44.4 | 14 | M12 | 1.6 |

| SSUCF 208 SB | 40 | 1.1/2 | 129 | 102 | 15.5 | 36 | 21 | 51.2 | 16 | M14 | 1.9 | ||

| SSUCF 209 SB | 45 | 1.5/8 | 1.3/4 | 136.5 | 105 | 17.5 | 38 | 22 | 52.2 | 16 | M14 | 2.4 | |

| SSUCF 210 SB | 50 | 1.7/8 | 1.15/16 | 2 | 142.5 | 111 | 17.5 | 40 | 22 | 54.6 | 16 | M14 | 2.6 |

| SSUCF 211 SB | 55 | 2 | 2.1/8 | 161.5 | 130 | 19.5 | 43 | 25 | 58.4 | 19 | M16 | 3.7 | |

| SSUCF 212 SB | 60 | 2.1/4 | 2.3/8 | 175 | 143 | 19.5 | 48 | 29 | 68.7 | 19 | M16 | 4.3 | |

| SSUCF 213 SB | 65 | 2.1/2 | 187 | 149 | 21.5 | 49.5 | 30 | 69.7 | 19 | M16 | 5.2 | ||

| SSUCF 214 SB | 70 | 2.3/4 | 193 | 152 | 24 | 53.5 | 31 | 75.4 | 19 | M16 | 5.8 | ||

| SSUCF 215 SB | 75 | 3 | 199 | 159 | 22.5 | 55.5 | 34 | 78.5 | 19 | M16 | 6.2 | ||

| Non stock sizes are available to order | |||||||||||||

SUC insert limiting speeds

The limiting speed of any ball bearing insert is, for practical purposes, determined by the quality of fit between the inner ring and the shaft.

| QCB Ref | Shaft tolerance | |||

| j7 | h7 | h8 | h9 | |

| SUC 201 | 6700 | 5300 | 3800 | 1400 |

| SUC 202 | 6700 | 5300 | 3800 | 1400 |

| SUC 203 | 6700 | 5300 | 3800 | 1400 |

| SUC 204 | 6000 | 4800 | 3400 | 1200 |

| SUC 205 | 5600 | 4000 | 3000 | 1000 |

| SUC 206 | 4500 | 3400 | 2400 | 850 |

| SUC 207 | 4000 | 3000 | 2000 | 750 |

| SUC 208 | 3600 | 2600 | 1900 | 670 |

| SUC 209 | 3200 | 2400 | 1700 | 600 |

| SUC 210 | 3000 | 2200 | 1600 | 560 |

| SUC 211 | 2600 | 2000 | 1400 | 500 |

| SUC 212 | 2400 | 1800 | 1200 | 450 |

Setscrew tightening torque

The 2 setscrews should be tightened to the appropriate torque figure. Over tightening may result in a fracture developing in the inner ring.

Should the axial load be high, a small dimple in the shaft may improve the locking effect. For best effect the bearings should be mounted against a shoulder in the shaft.

| Size | Torque (Nm) |

| M6 | 4 |

| M8 | 8 |

| M10 | 15 |

Materials

QCB® Stainless Steel bearing units are made in high quality stainless steel for maximum corrosion resistance.

All pillow blocks and flange units have a solid base and smooth exterior surface restrict the growth of bacteria.

| Part | Material | ||

| bearing insert | Inner and outer rings | Stainless steel | AISI 440C |

| Balls | AISI 440 C | ||

| Cage/retainer | AISI 321 | ||

| Flinger seal | AISI 321 | ||

| Set screws | SU 304 | ||

| Rubber seals | Nitrile rubber | ||

| Housing | Housing body | Stainless steel | AISI 440 C |

| Grease nipple | AISI 304 |

Food Grade Lubricant

QCB® Stainless Steel SUC inserts are lubricated with KLUBER PARALIQ GA343 grease

| ndm value | Environmental conditions | Temperature | Relubrication interval |

| < 40 000 | Clean | -15 to +65 °C | 6 - 12 months |

| +65 to +100 °C | 2 - 6 months | ||

| < 70 000 | Clean | -15 to +65 °C | 2 - 6 months |

| +65 to +100 °C | 1 month | ||

| Any | Dirty / Water splash | Any | 1 month |

Operating temperature range

QCB® Stainless Steel inserts can operate in environments from -30 to + 120C

(PDF) 945.49 KB